In August 2023 I bought my first serger, a Brother ST4031HD that I bought on Amazon for $379.99. I paid a $100 premium for this “heavy duty” version rather than the very popular Brother 1034D, which is a very similar machine but known to struggle with serging fleece and heavy fabrics. Even so, it is still on the low end of serger pricing but offers pretty good bang for the buck as far as being a perfectly functional serger at a very reasonable price point, that is not too difficult to thread because it comes labeled with a color-coded threading system.

Even with the color coding, there was definitely a learning curve to figure out how to thread it and I did have to watch the YouTube video multiple times and use the tweezers it comes with. And sometimes I had to fiddle with the four tension adjustment knobs. And I did try to just use grey thread for as long as possible so I wouldn’t have to rethread the machine very often. And the machine sure does make a racket. Even so, I would probably have been content with this starter machine for quite some time, except that about a year after I bought it, I did something I shouldn’t have and broke it. I’m not actually entirely sure what I did, but in the process of disengaging and re-engaging the knife blade, I managed to swing the knife around into a position that it should not be possible to get it into and the only way I could figure out to get it out was to unscrew the blade, take it off, and put it back on again. I did that, but the knife would not cut any more. I took it off and put it back on again multiple times and then brought in my husband to try. He could not get it to work either. We inspected the blade and saw no signs that it was broken, and yet, it would not cut. I tried to order a replacement blade and found that the official replacement blades for this machine are very difficult to get and cost over $100.

So I took the machine to a sewing machine repair shop and asked them what to do. They refused to accept my “disposable” serger for repair, telling me that their minimum price for putting it on their repair bench would not be worth it for such a cheap machine. I did get the repair technician to take a peak without putting it on his repair bench, and he couldn’t find anything obviously wrong with it but thought it couldn’t hurt to try changing the blade. The repair place also sold sergers so I took a look at a couple of Baby Lock sergers they had on display and was intrigued.

When I got home I went back to searching for blades and found that inexpensive blades that fit other Brother models, such as this one, reportedly worked with the ST4031HD even though they were not advertised for that machine. So I ordered a new blade for $13.98 and then browsed the Baby Lock website. (We eventually fixed the Brother serger after my husband realized that the knife holder had been upside down when we screwed in the knife — it had appeared symmetrical but he finally noticed that it wasn’t. We rotated it 180 degrees and everything worked fine. But by that point I had already ordered a new serger.)

I started reading about Baby Lock sergers — they all have really positive sounding names. I started with the inexpensive Baby Lock sergers and worked my way up. Each machine had more features and I wanted all of them. Air threading, YES. No tension adjustments, sign me up. If I’m going to buy a new machine I want one that doesn’t require tweezers to thread or tension fiddling for every different kind of fabric. I was ready to buy a Baby Lock Victory (list price $1,649) but then I realized that it’s threading was only partially automatic. The Acclaim (list price ($2,749) had a more advanced threading and tension adjustment system. But then I realized if I went up a step to the Accolade (list price $3,849) I could also get cover stitch features. I had considered previously whether to get a serger or a combo serger/cover stitch machine, and settled on just a serger because the reviews of most of the combo machines complained that it was too much of a hassle to switch machines between serging and cover stitch mode. But, if the machine could thread itself automatically, maybe it wouldn’t be so bad. Maybe I do want a combo machine. I kept reading the web site and finally got to the ultimate Baby Lock serger: the Triumph (when they inevitably come out with a new model that is better than this one, what will they call it?). It is a combo machine with all the features of the Accolade, and a few extras, but most importantly, it has a knee lift. My Bernina sewing machine has a knee lift that I absolutely adore. It let’s me raise and lower the presser foot with my knee, without having to take my hands off the fabric. Since I use the same leg to run the peddle, I never accidentally start sewing without lowering the presser foot. In contrast, my Brother serger does not have a knee lift and I regularly forget to lower the presser foot, start sewing, and end up with a nasty thread nest. The knee lift sold me on the Triumph, but I was taken aback by the $5,499 price tag (typically available for about $500 less at sewing machine stores) — and the fact that buying all the accessories I might want for it would cost even more (another $1,500 or so).

I decided to read some reviews of Baby Lock sergers and watch some videos to see how easy or difficult they looked to use. I stumbled upon a review titled “Was it Worth it? Why I bought Babylock Accolade Serger Coverstich Machine” by Jessica Capalbo. I don’t know if Jessica gets a commission from Baby Lock, but by the time I got through her 6-minute video, I was completely sold. Besides her account of how much easier it was to sew with a high-end serger, her justification to spend the money on a serger if your hobby is sewing since other people spend money on ski vacations, completely resonated with me. I would have bought an Accolade right then and there, but I really wanted that knee lift, which required stepping up to the top-of-the line Triumph. In some of the Facebook sewing groups, people had mentioned getting good deals on refurbished Baby Lock machines so I checked out eBay, and sure enough found several Triumphs for sale. I found one in excellent condition that came with all the books and almost every extra foot (in a handy carrying case) and accessory that Baby Lock makes for this machine (not including a trolley — it is huge and if you want to take it anywhere you really do need a trolley with wheels) plus a DIY 3D printed thread bin that someone had made as the machine doesn’t come with a thread bin, all for $4,128.95. I decided to buy it, and a few days later it arrived on my doorstep.

(Incidentally, I briefly also considered the Bernina L-890, which is a similar high-end combo machine that also has a knee lift. People seem to really like the fact that a lot of the control is through a touchscreen with good instructions. But it’s list price is $7,999 and it’s fairly new and so it doesn’t have much of a used market.)

The first time I threaded the Triumph, I followed the instructions in the manual very carefully. It took some time to fully understand some of the diagrams, but once I understood what I needed to do I succeeded in threading it properly with four spools of black serger thread on my first try! With just a few adjustments to stitch height and width, I produced nicely balanced 4-thread serging stitches. I immediately noticed that the Triumph was much quieter than my Brother serger and sewed much more smoothly. I had two pairs of black pants cut out so my first project was to sew them.

After my triumphant first projects, I was traveling and busy for a couple of weeks. My next project was to serge the unraveling edges of a green shawl that a friend brought me. I showed her my Triumph, unthreaded the black thread, and started trying to thread the green thread. Only this time I didn’t read the manual carefully enough and inadvertently skipped some essential steps. I had to unthread and rethread a couple of times and learn how to change the needles after I broke one. But eventually I got it sorted out and produced a beautiful serged edge. After my friend went home I unthreaded and rethreaded the Triumph twice to make sure I could do it. I would say it is still not completely trivial and I could still easily forget a step, but threading a serger completely without the use of tweezers and having it sew perfectly without any tension adjustments is really awesome.

I mastered 3-thread and 4-thread overlocking with the Triumph and then tried stitching down quarter-inch clear elastic by threading it through the slot on the standard presser foot — it was very easy! I sewed two pairs of Pattern Emporium Urban tapered pants (from black ponte and grey Polartec sweatshirt fleece), a double-knit Sinclair Alana dress, and a Pattern Emporium Sweet Cheeks sweater from purple Polartec sweatshirt fleece.

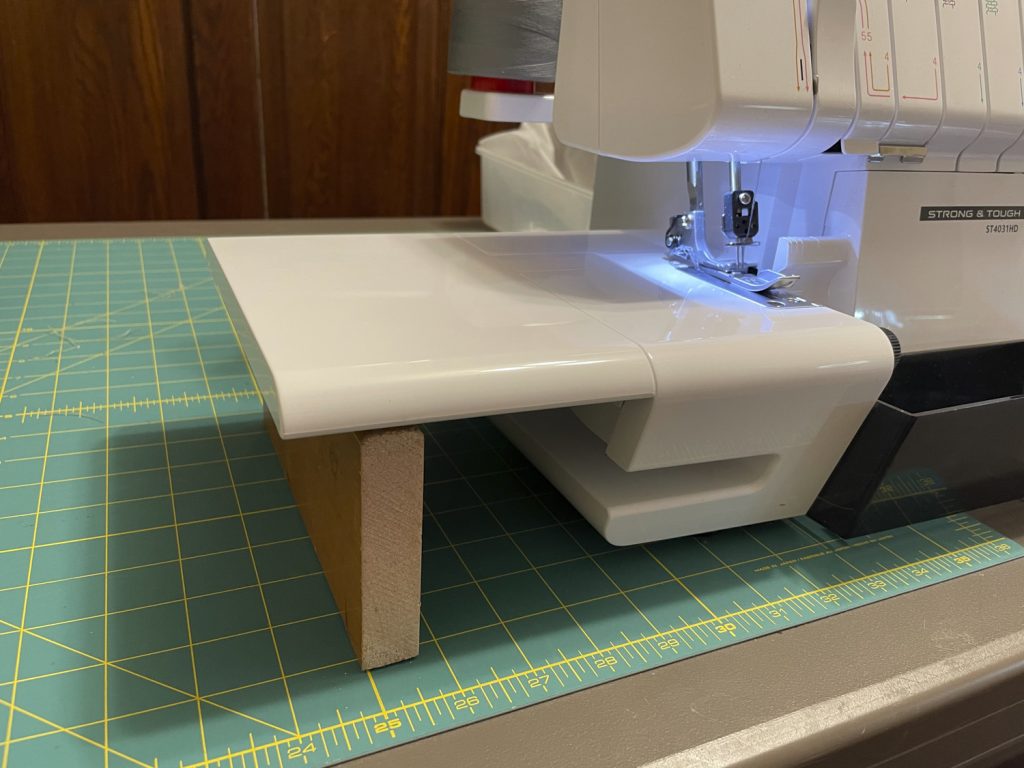

I read through the accessory book and watched a video on using the overlock table and fabric guide accessories and gave them a try. The table has a slot for the serger knife and gives you a bigger surface for serging and allows you to use accessories that normally would not work in overlock mode. The fabric guide makes it easier to sew a straight and consistent distance from the edge of the fabric. It will be quite some time before I figure out how to use all the other feet and accessories, and even though in theory you can sew with 8 threads at the same time, I probably won’t try it any time soon.

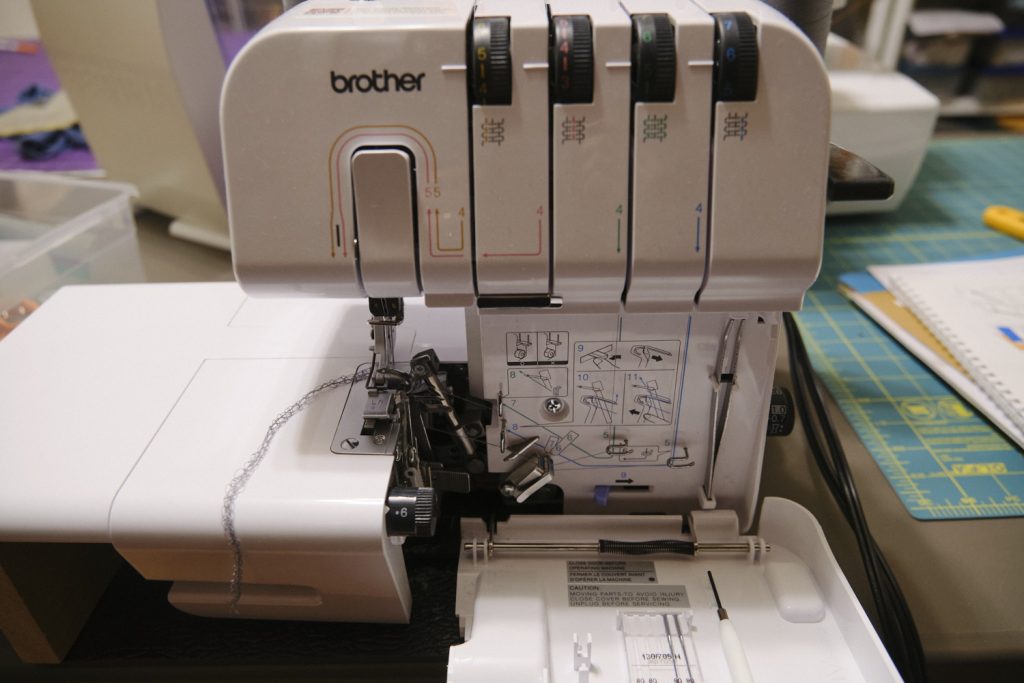

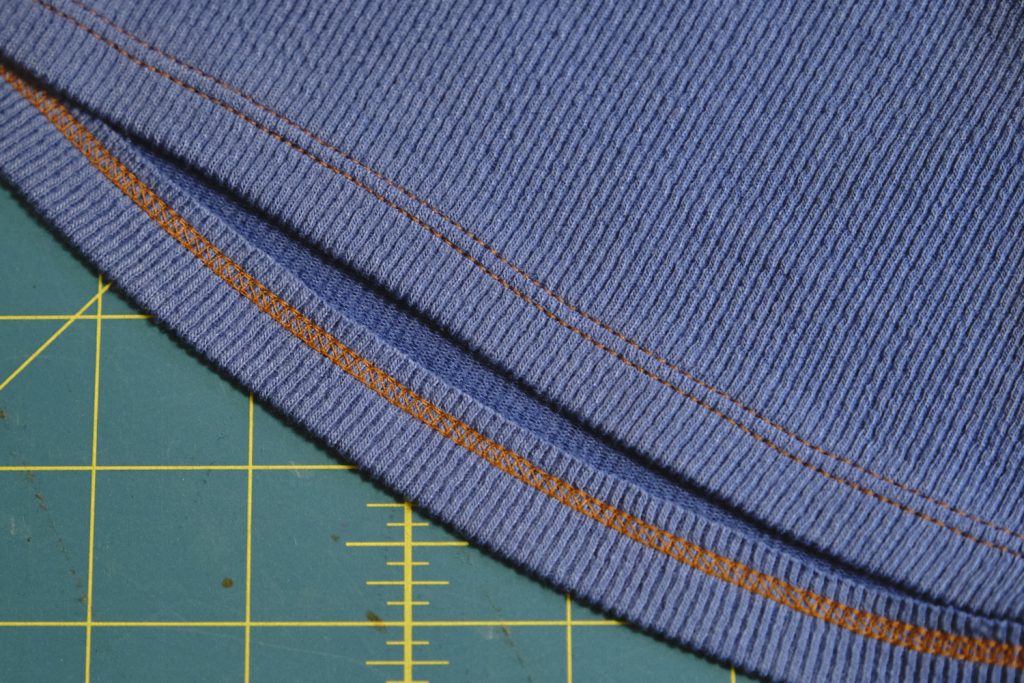

I finally worked up the courage to try cover stitching. This requires getting the included small screwdriver out of the convenient side compartment, unscrewing and removing the two needles, moving the needles over into cover stitching position and screwing them back in. While I was at first taken aback by the need to use a screwdriver and move the needles to switch back and forth between serging and cover stitching, it was actually pretty easy to do. It is easy to align the needles and see whether they are properly in place before screwing them in, and if you accidentally drop one while screwing it in there is a convenient drawer with a magnet to catch the needles that slides out from the bottom of the machine so you can retrieve the dropped needle without having to open or lift the machine. I selected the wide cover stitch and followed the instructions to setup three spools of thread. I sewed some practice cover stitches on some heavy sweatshirt fleece and admired the results. Then I tried a stretchy rib knit and was not as happy. After adjusting a few settings I decided that this stretchy fabric would be better off with a narrow cover stitch. I moved one of the needles and rethreaded it and tried again, and was pleased with the results. When I was done cover stitching I moved the needles and threads back to serging position without too much difficulty. I can see why a lot of sewists prefer to have a separate cover stitch machine as it would be annoying to have to switch back and forth multiple times during a project. However, I think as long as I’m doing most of my cover stitching together at the end of a project, switching is not too bad.

For my first big combo project I ended up serging four shirts and then cover stitching the bottom hems and sleeve hems of all of them at once. The shirts are made from a soft rayon/nylon/spandex Monaco rib knit from Mily Mae Fabrics. I used the Sinclair Demi and Tao patterns for the raglan shirts and the Sinclair Bondi pattern, cropped to the waist line for the short-sleeve shirt. I also used Bondi and color blocked the sleeves for the last shirt.

And I made a Sinclair Kai for my husband from a cotton lycra yarn-dyed rib knit in colors that coordinated with the kids’ shirts. (I’m wearing a Pattern Emporium Sweet Cheeks sweater in this photo that I made last winter in a cuddly brushed hacci sweater knit.) I was able to switch the serger back to serging mode and switch to off-white thread pretty quickly. But I was pressed for time and a bit lazy so I just zigzagged the hem on my sewing machine rather than switching it back to cover stitch mode again.

I’m looking forward to a lot more triumphant sewing yet to come!